On-time and error-free production orders.

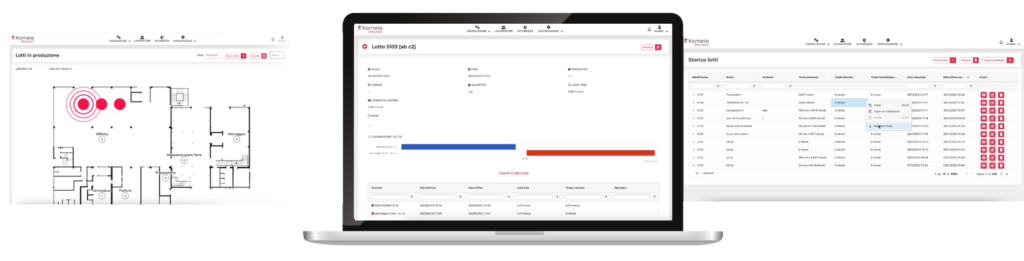

View your production orders in real time on a live factory map.

Identify potential bottlenecks or delays in advance with predictive alerts and reports.

Ensure on-time delivery with real-time order visibility and predictive insights.

How does it work?

3 cm sensors physically track order sheets, work-in-progress bins, or parts.

The sensors are detected by fixed antennas installed at workstations and storage areas.

Production orders are displayed on a digital representation of the factory within the software.

Discover Komete at no cost

Discover how Komete can help your company deliver on time and reduce coordination costs.

Our strengths

No integration required

Can operate completely independently from existing IT systems.

Plug & Play

Antennas mount on existing structures and communicate via Wi-Fi.

Automatic data collection

Progress and traceability are captured automatically, with no operator input.

What benefits does a Komete bring ?

On-time deliveries, thanks to predictive alerts on delays or bottlenecks.

Lower coordination costs, with intuitive and transparent visualizations of production progress, accessible to everyone.

Fewer organizational downtimes, caused by missing materials or orders placed in the wrong workstation.

Reduced inventory costs, for work-in-progress items and materials in transit.

Stronger coordination between logistics and production areas, ensuring a continuous and interruption-free workflow.

Higher accuracy in job costing for custom production orders, supported by objective, real-time data.

About us – Smart Factory Made Easy

Manufacturing DNA

We come from the manufacturing world and know its challenges firsthand.

Today, competitiveness stems from agile processes, not just advanced machinery.

Our mission is to give companies a competitive edge through simple and fast technologies.

Learn more

Discover how Komete helps you ensure on-time deliveries, reduce coordination costs, and automate data collection to optimize production and logistics.